The international and local electronics industry is frequently under pressure, which is propagating companies to employ resilient strategies for growth. Global pandemics, natural disasters, and economic meltdowns have revealed the many vulnerabilities in the international supply chain, and stakeholders must plan and devise means to respond when these challenges arise.

On the other hand, local supply networks are, in some cases, emergency response options for the supply chain, and electronic manufacturers must find ways to be flexible with their approach to supply chain partnerships. Balancing your supply network between local and international partners could be crucial to staying in business when these challenges happen, and we will discuss this in detail in this article.

Table of Contents

What Do We Mean by Globalization and Localization in Electronics Sourcing?

The electronics supply chain is a different place to do business. Finding the ideal balance between being local and expanding globally while staying up to date with all the upcoming digital changes is the key to developing resilience in today’s market. Instead of choosing between being a global player or focusing on local markets, smart companies are learning to do both. Consider building flexible local operations that fit into the bigger global picture.

The trick is to spread your resources worldwide, setting up production and distribution hubs close to your key markets and leveraging the power of technologies such as procurement management software for efficiency. This way, you can quickly adapt your operations when markets shift or unexpected disruptions happen. However, to achieve both globalization and localization in this technology-driven industry, you need advanced tools such as electronics BOM management tools and other supporting tech stacks backing you up. Real-time data, smart forecasting tools, collaboration platforms, and procurement systems are all vital in enabling all stakeholders to work together for growth both internationally and locally.

Electronics manufacturing companies must realize that staying competitive means being able to pivot quickly when market disruptions occur and relocate resources around efficiently. It’s not just about keeping up anymore – it’s about staying ahead of the curve.

Why Globalization Seems So Appealing

Being a part of the global electronics market has many benefits and can be profitable when strategically managed. Over-reliance on the global market is sometimes risky when there are no alternative investments in local markets to shoulder costs in times of market disruptions. We have seen how globalization has been the backbone of many supply chains. But the impact of trade wars, regional crises, government instability, and protectionist policies could hinder the ease of doing business in the global market. This reality forces companies to evaluate their profits on the global scene to determine the stability and resilience they could achieve in their various local markets.

The Growing Appeal of Localization

Local supply chains are becoming increasingly important in electronics manufacturing. While global supply chains have their advantages, going local often gives businesses a more resilient edge and fewer supply chain headaches. By distributing its manufacturing and storage facilities around several localities, businesses can avoid becoming too dependent on a centralized supply chain structure for expansion. The financial gains of localization, which include saving on shipping costs and getting products to customers faster, are crucial in the electronics industry, where things move at unprecedented speed, and market demand can change overnight.

This is happening right now: a lot of firms who once depended largely on Asia are suddenly opening stores in North America and Europe. They may not necessarily be abandoning their Asian operations but are building a more balanced approach.

It’s about avoiding supply chain interruptions, being nearer to clients, and having the flexibility to quickly adjust to changing market demands.

Finding the Sweet Spot: Hybrid Models

The electronics supply chain will need to rely on hybrid models, and companies in this industry must find ways to balance their global operations by incorporating a local presence. Technological innovations such as electronics BOM management software, procurement management software, collaboration platforms, and other tools can be employed to manage both global and local operations seamlessly.

Finding the sweet spot is about knowing where to strike a balance that makes your businesses more resilient to global disruptions while tapping into local advantages and maintaining efficiency. Evaluate which markets bring the most benefits for cost savings, resilience, and sustainable practices, then adapt your hybrid operation to fit your objectives.

The Challenges You’ll Face Along the Way

Electronics companies need to rethink their supply networks and come up with ways to get over the challenges of resilience. Decentralizing international operations and opening stores in regional markets necessitates large infrastructure, personnel, and equipment investments. Additionally, there is a need to plan for the technical aspect of this move. Data and company information from global operations will need to be synced with local ones to ensure a seamless approach to generating insights for profitable decision-making. Companies must also be ready to fight for market share and supply chain networks with existing local competitors.

Finding Your Perfect Balance

Businesses must use digital technologies for transparency and resilience while adapting their local and global strategy flexibly if they want to succeed. Platforms like Luminovo are committed to providing innovative electronics BOM management software and supporting businesses on this critical transition with tools and technologies for seamless management of local and global operations.

Share your thoughts and experiences balancing global and local electronics sourcing operations in the comments.

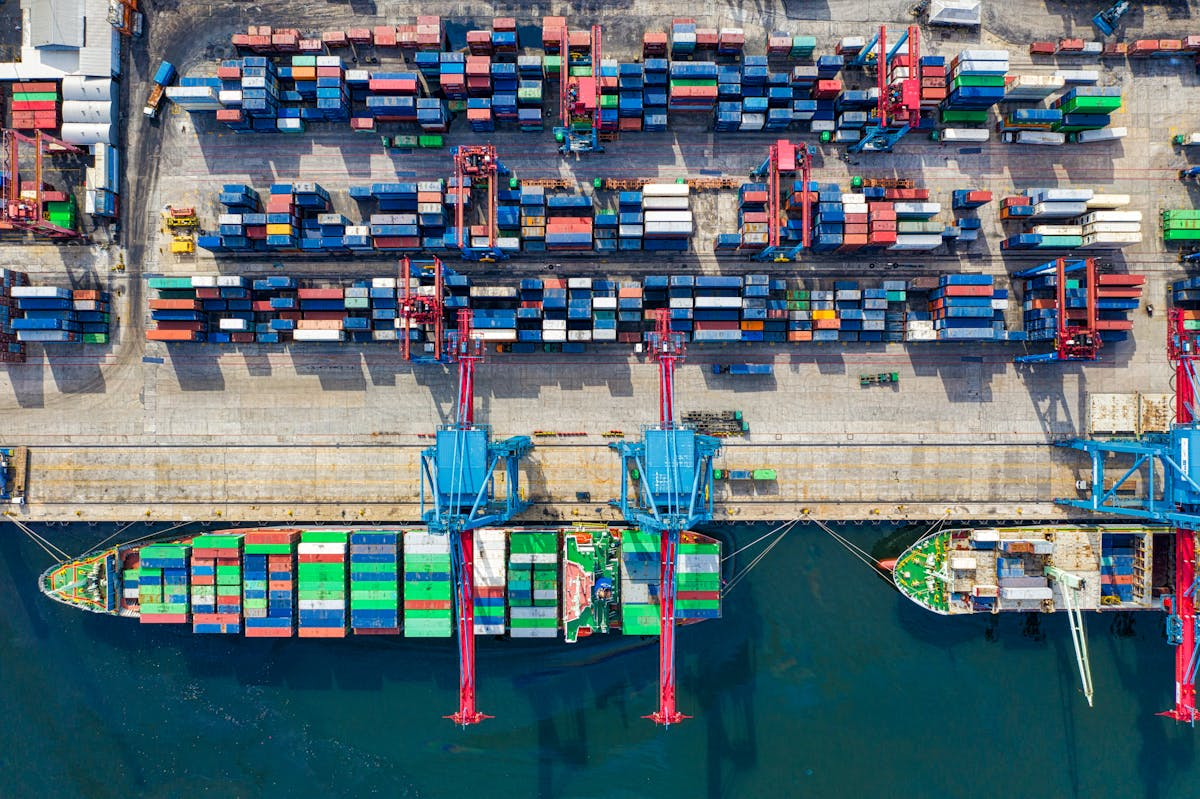

Featured image source: Freepik

Andrej Fedek is the creator and the one-person owner of two blogs: InterCool Studio and CareersMomentum. As an experienced marketer, he is driven by turning leads into customers with White Hat SEO techniques. Besides being a boss, he is a real team player with a great sense of equality.